Machines

Home > Machines

Home > Machines

We use essential cookies to offer you a better website experience. We would like to use other cookies to analyse our website performance and personalise our offers, but only if you agree.

Learn more about your options in our Cookie Policy

Cookies Preference

This website uses the following types of services.

Cookie Policy

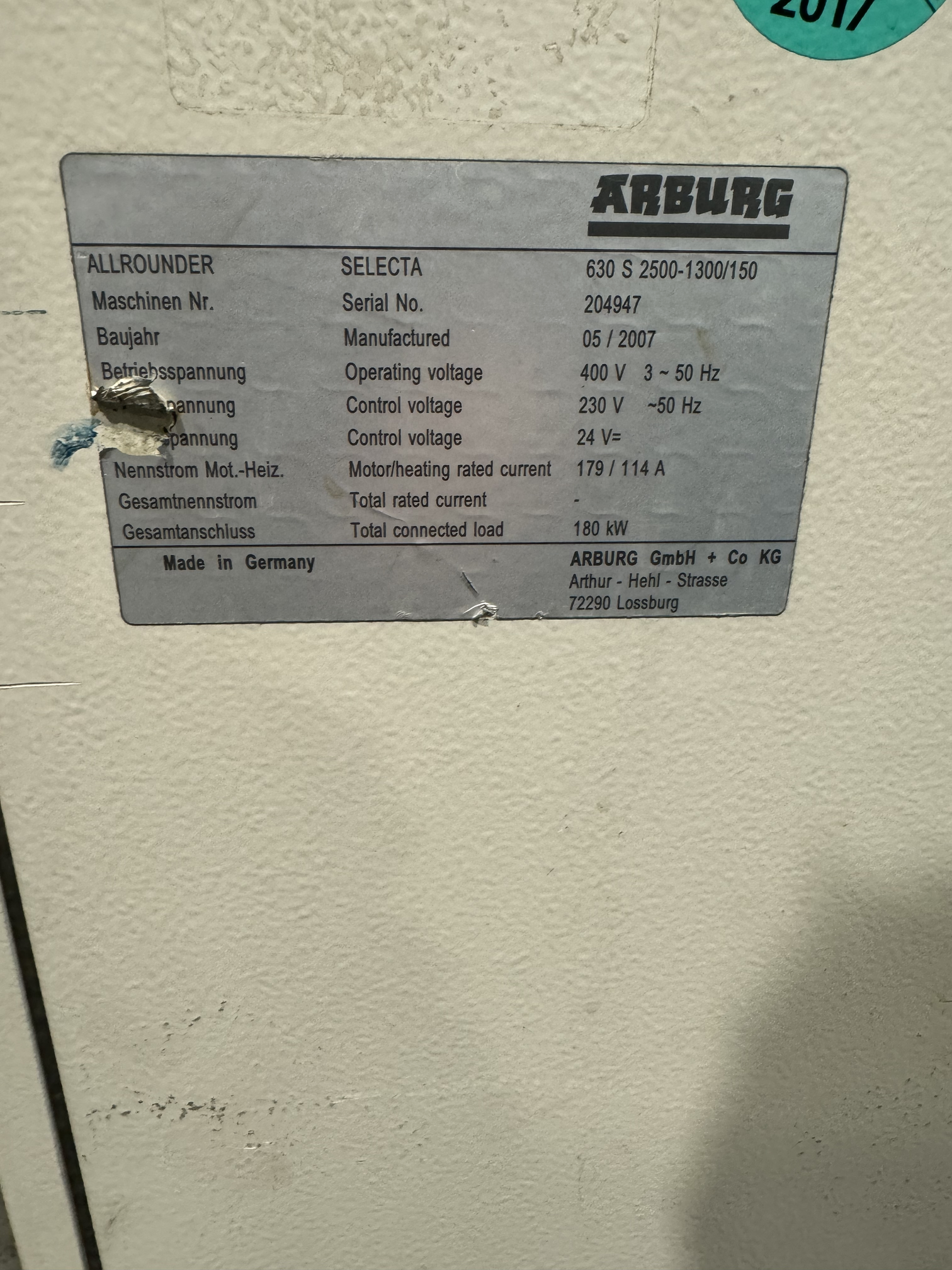

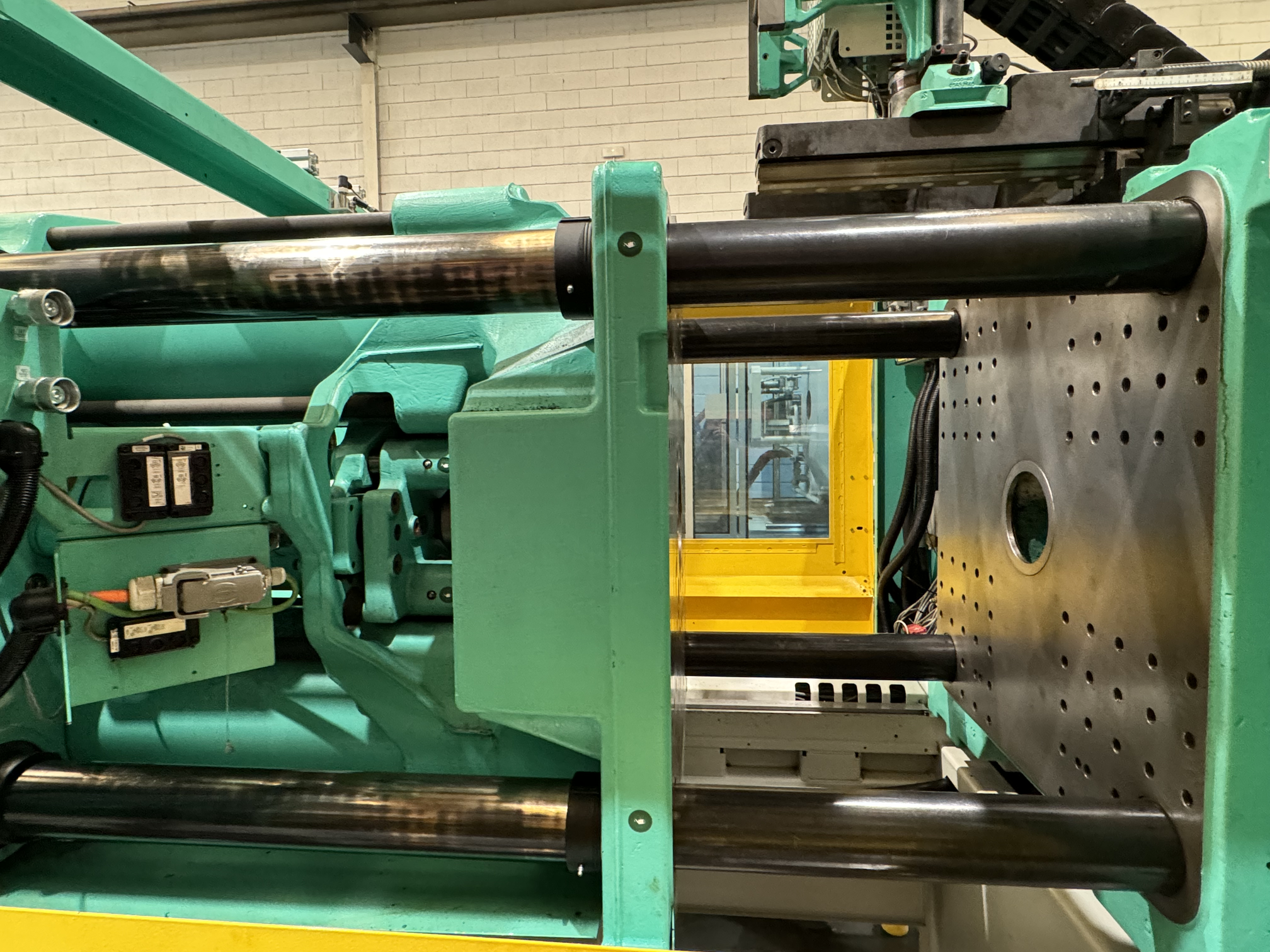

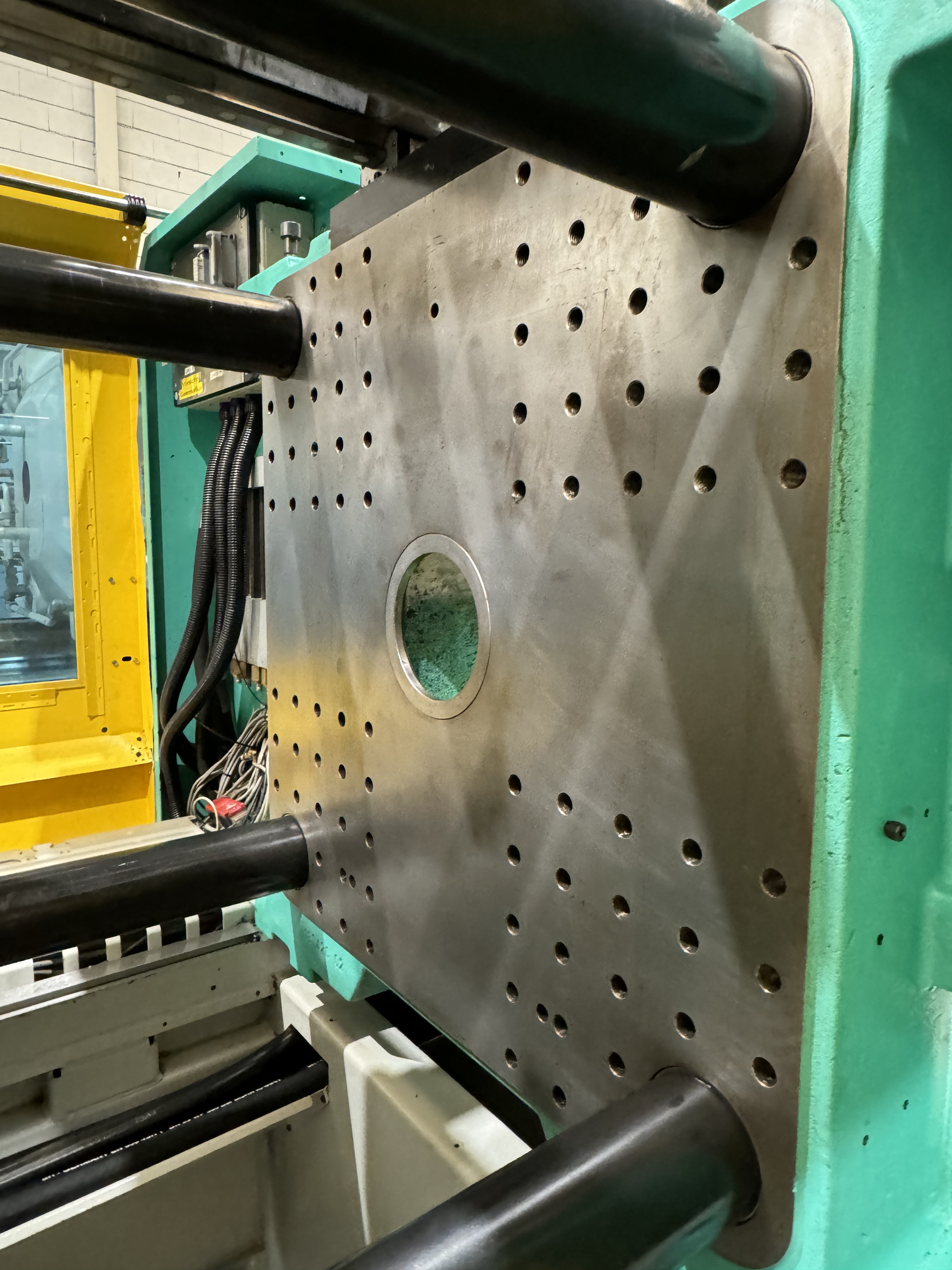

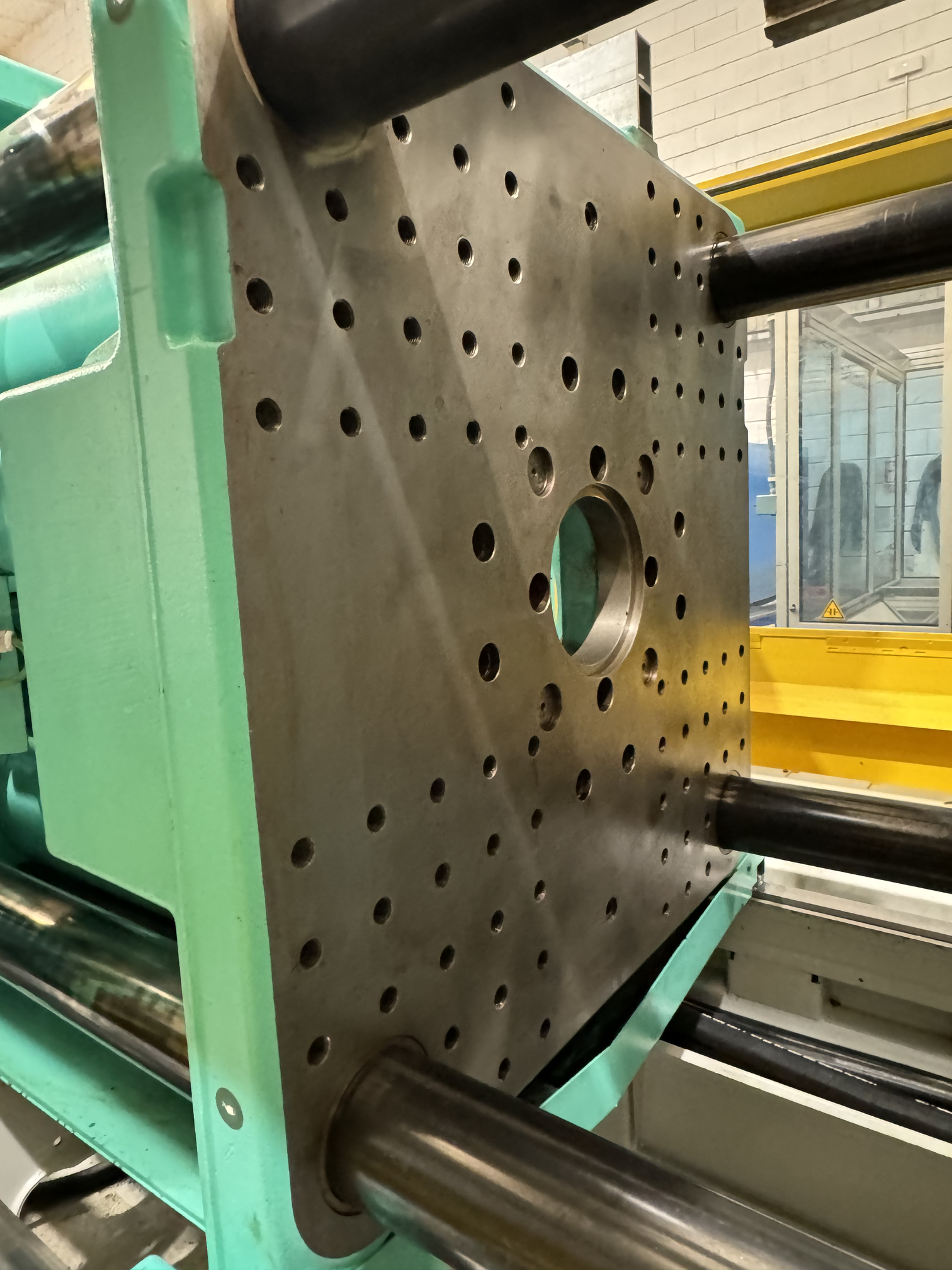

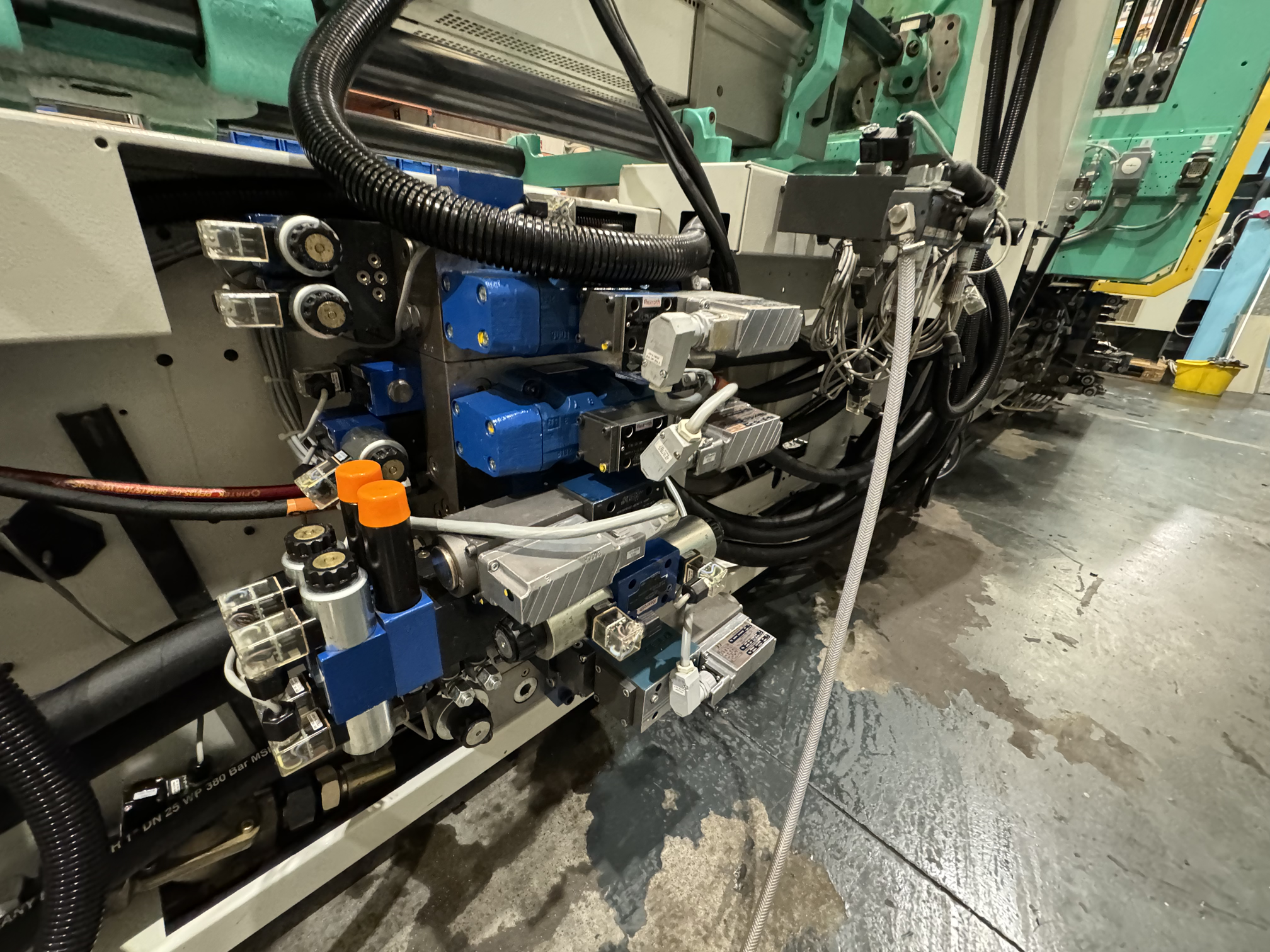

Multicomponent IMM brand Arburg (vertical/horizontal) 250 tons of clamping force. Year 2007. 50.000 working hours. Screws diameter (55/25). Machine will be delivered full checked tested and operative RE-Conditioned by Transitus team. We can offer the service of start up in your factory. Ask us for more info.

| Technical details | |

|---|---|

| SHOTWEIGHT | 510/45 gr PS |

| SCREW DIAMETER | 55/25mm |

| INJECTION PRESSURE | 2380/2500 BAR |

| INJECTION VOLUMEN | 558/82 cm3 |

| MIN. MOULD HIGHT | 300mm |

| DAYLIGHT MAX | 900-300mm |

| TRAVEL OPENING | 600mm |

| DISTANCE BETWEEN TIE BARS (h x v) | 630x630 |

| PLATEN SIZE | 900x900mm |

| CLAMPING FORCE | 2500 kN |

| YEAR OF BUILDING | 2007 |

| WORKING HOURS | 48.934 |

If you want to sell a machine you can contact us without any commitment.

The sequence of our work when reconditioning a machine consists of the following points.

View InformationGeneral cleaning of the whole Injector and replacement of broken parts.

Checking, repairing and adjusting the electrical system.

Hydraulic system check.

Mechanical functional check.

Safe Shipment.